Collapsing Process at the Ends of 48 Pipes in Construction Scaffolding Systems with Metflex Pipe Presses

The quality and durability of construction scaffolding systems are extremely important for the construction of safe and robust structures in the construction industry. The pipes used in scaffolding systems must have a high bearing capacity and must be joined correctly to ensure stability. Metflex pipe presses are important equipment that makes the production of such systems safer, faster and more efficient, especially with the strangulation process performed at the ends of the 48′ pipes. In this article, the importance of Metflex pipe presses’ choking process for male ends of 48′ pipes in construction scaffolding systems will be discussed.

You can see all our domestic and foreign companies that use our machine by producing in the construction scaffolding sector from our References section.

Working Principle and Features of Metflex Pipe Presses

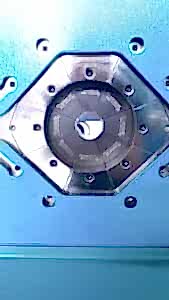

Metflex pipe presses are pipe forming machines and are generally used for special processes performed on the ends of pipes. These presses provide the shaping of pipes through hydraulic or mechanical systems. Pipe presses apply high pressure to shape the metal and increase its durability. Metflex pipe presses are extremely effective, especially for giving special shapes such as male ends attached to pipe ends.

Use of 48 Pipes in Construction Scaffolding Systems

Pipes used in construction scaffolding systems should be generally manufactured from steel material and designed to be suitable for various shape changes. 48′ tubes are commonly used to form the main components of scaffolding. These pipes are used to create a solid platform for the safety of workers, to set up temporary structures around structures and to facilitate concrete casting works.

In construction scaffolding systems, special processes may be required at the ends of the pipes. These operations are critical for connecting the pipes together, ensuring safety during installation and increasing durability. Metflex pipe presses are used to choke the ends of 48″ pipes in order to add male ends to the ends of the pipes. This process ensures that the pipes are connected to each other more securely and the scaffolding system operates more safely.

What is Strangulation and Why is it Performed?

Choking is a process performed to ensure a more robust connection of the pipes to each other by giving a special shape to the pipe ends. This process is done by adding male ends called “taklan” to the end of the pipe ends. Taklan means that the end of the pipe is shaped outwards and then becomes suitable for connecting to another pipe.

In this process, the Metflex pipe press applies high pressure to the end of the pipe, moulds the pipe and turns the end of the pipe into a male end with a choking process. This process provides extra safety at the connection points of the pipes. In addition, the choking process makes the installation of the pipes faster and more efficient, because the connection points can be adapted to each other more easily thanks to the plug ends.

Advantages of Metflex Pipe Presses with the Choking Process

- Durability; Thanks to the strangulation process, the end parts of the pipes become more durable. This ensures the safe use of scaffolding systems for a long time and increases the heavy load carrying capacity.

- Easy Installation and Connection; The choking process facilitates installation by adding male ends to the ends of the pipes. This saves labour during construction and helps projects to be completed on time.

- Safety; Thanks to the inserted ends, the pipes are connected to each other more securely. This increases the safety of scaffolds and helps protect workers from accidents.

- Cost Effectiveness; Thanks to the choking process of Metflex pipe presses, the production process is accelerated and higher quality connections are obtained with less labour. This reduces the overall costs of construction projects.

- Fast Production and Efficiency; Since Metflex pipe presses perform the strangulation process quickly, the production process is very efficient. This saves time on large projects and allows projects to be completed more quickly.

Metflex pipe presses play an important role in construction scaffolding systems with the suffocation process performed on the ends of 48 pipes. This process ensures that the pipes are connected to each other firmly and that assembly is fast and efficient. It also increases the safety of scaffolding systems, reduces labor costs and helps projects to be completed in a shorter time. These advantages provided by Metflex pipe presses are of great importance in increasing the quality and safety of scaffolding and formwork systems in the construction sector. This technology offers an important innovation in order to ensure the success and safety of construction projects.